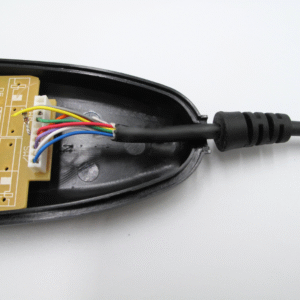

Kingstec recently worked with a leading company in the healthcare sector that produces cutting-edge hospital beds. The client was struggling to solve a common and ongoing problem involving controller cable assembly durability and failure, which had been causing unreliable, intermittent connections and potentially dangerous exposed wires. Cables could be easily pulled out of connectors, creating faulty, unstable connections. The client was also concerned about the potential risk to end users (typically nurses and caregivers), who they found were often attempting to fix the damaged cables themselves.

Broken & intermittent bed controller

The client approached Kingstec to improve the durability of their cables and connectors, which they hoped, would increase the products’ service life and reduce failure rates.

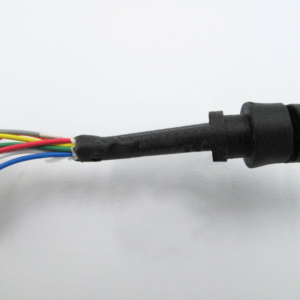

Kingstec's team of engineering experts assessed the client's needs and identified the main issues facing end users. To solve these issues, the team added a groove (or slot) on the Strain Relief (SR), which not only allowed for a solid mechanical connection between the cable and controller housing, but also provided the sealing needed to prevent debris or cleaning solutions from getting into the controller.

Overmolded slot on strain relief solution

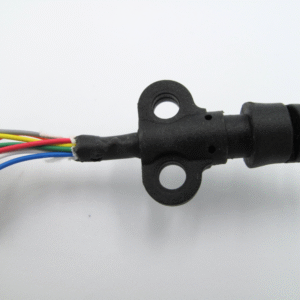

The team also added extra “Elephant Ears,” which were molded in to physically lock the cable to the housing, making it much harder for the cable to be pulled out.

"Elephant ears" to mechanically fasten cable to plastic housing

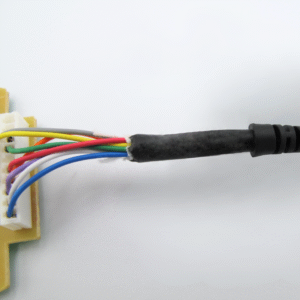

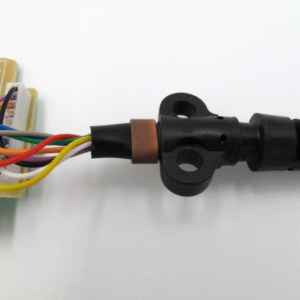

To then further secure the inner wires of the cable to the cable jacket and plastic housing, a metal stayband was crimped in front of the overmolded strain relief, providing a more robust and physical connection to the housing and cable. This increases the pull force of the cable and enhances its durability.

Metal/copper band crimped, or fastened to lock coloured wires to black cable jacket

The implementation of a slotted strain relief that captures the housing, “Elephant Ears,” and the metal stay band, created an innovative solution that improved cable durability and safety for end users, as they were less likely to attempt repairs themselves. As a result, our client has seen a significant reduction in the rate of product returns and an increase in quality and customer satisfaction.