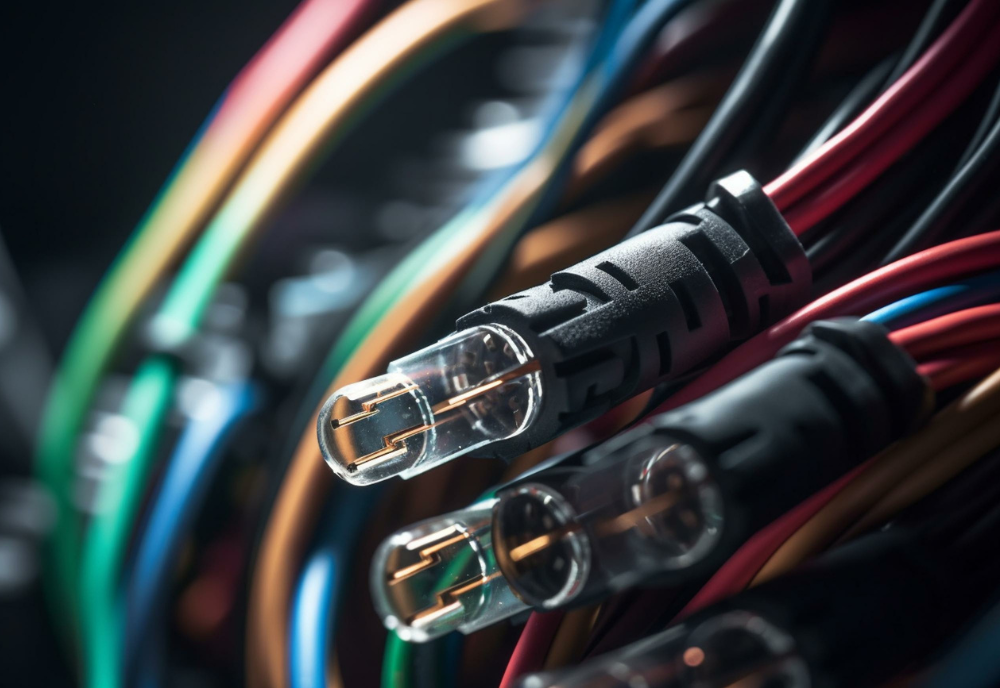

Overmolded cable assemblies are the unsung heroes of modern technology, seamlessly integrating electrical and mechanical components into single, robust units. From enhanced durability to tailored aesthetics, these customizable cable assemblies play a pivotal role in a wide range of industries, elevating the performance and reliability of electronic devices.

Let’s take a closer look at overmolded cable assemblies:

A custom cable assembly is a bespoke cable system, combining cables, connectors, and related components into a singular configuration that meets the unique specifications and demands of a particular application or project.

To produce these cable systems to the exacting requirements of our customers, Kingstec's in-house engineering team often crafts solutions from the ground up, acting like architects, to ensure these assemblies adhere to precise specifications.

Cable overmolding is a manufacturing process that has streamlined the way wires and connectors come together, resulting in cohesive, more durable single units. This technique has widespread applications across industries due to the enhanced strength, protection, and versatility it offers to cable assemblies.

By encapsulating cables and connectors, a technique Kingstec is renowned for, overmolding provides a protective shield, making cable assemblies resilient even in the most demanding environments.

Here are some of the benefits of overmolded cable assembly:

Ultimately, opting for custom overmolded cable and wire assemblies is an investment in both the durability and functionality of your electronic systems.

Overmolding a cable assembly is a precision process where material is injected into a mold cavity under significant pressure. This material molds over the cables or wires during insertion into an insulated or non-insulated raceway or connector, effectively sealing and protecting the connection point. This transforms a basic cable assembly into a robust, sealed, and customized component.

Materials for overmolding mainly include low-temperature polyethylene for inner molds and PVC for overmold, with the final choice usually dependent on desired durability, aesthetics, and performance characteristics. These materials, along with injection molding technology, enhance the cable's durability, appearance, and performance to meet diverse application demands.

Let's take a closer look at the steps involved in the injection molding process of overmolded cable assembly:

Designing overmold tooling demands precision, as any mistake can impact production costs, cycle times, and product quality. Precision is especially crucial for complex projects with multi-cavity molds and high volumes.

Advanced prototyping via 3D printing has helped in this area, allowing for easier and more cost-effective testing, and helping to reduce costs, lead times, and waste. This includes spatial fitting, a technique that involves 3D printing connectors in their assembled positions to assess fit, clearance, and potential environmental interference.

Nevertheless, in the realm of overmolded cable assemblies, design is key, and choosing the right manufacturing partner can make all the difference. Over the last 20 years, Kingstec has successfully completed over 5,000 projects, providing tailored overmolded cable assemblies and high-volume production with quick turnaround times, ensuring performance and durability.

The adaptability of custom overmolded cable assemblies, coupled with custom color and branding options, have made them a popular choice in applications where visibility, aesthetics, and reliability are of utmost importance. They are invaluable, for example, for cable assemblies in extreme weather conditions.

Here are some common applications of overmolded cable assemblies:

When you work with Kingstec, you benefit from decades of experience in engineering, logistics, and business solutions. We take pride in being a leading provider of custom cable assemblies, wire harnesses, and overmolded connectors, serving a diverse range of industries and applications.

Over the last 40 years, we have specialized in medical applications, including healthcare equipment, patient monitoring cables, power, coaxial, ECG, fiber-optic cables and complex high-termination count wire harnesses. Our expertise extends past the healthcare sector, though, providing:

Call us today to learn how your business can benefit from high-quality, well-designed, custom cable assemblies, wire harnesses, and overmolded connectors.