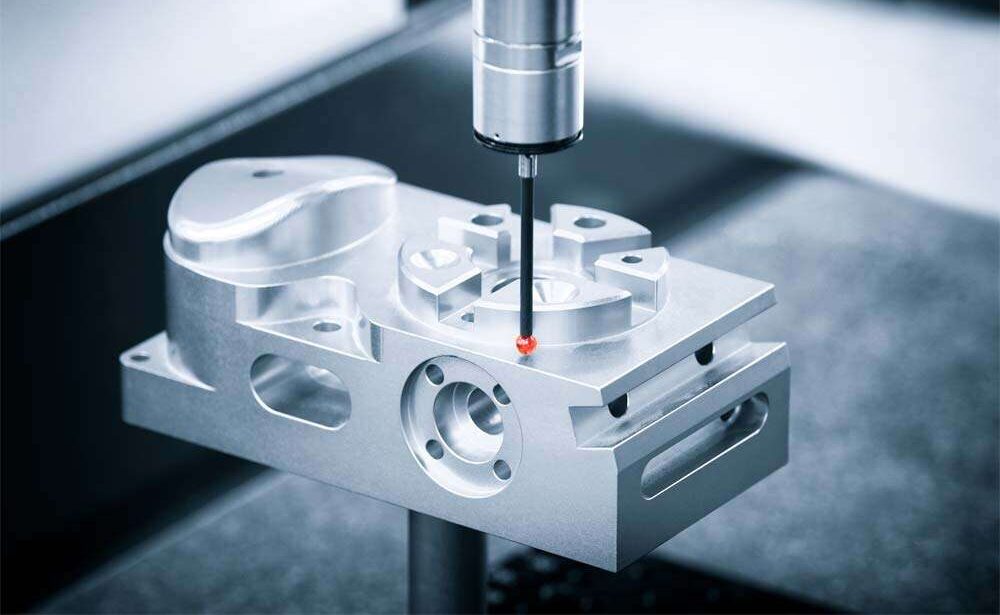

Kingstec delivers precision machined components produced with advanced Japanese and Swiss CNC and screw machining equipment to achieve tolerances as tight as 0.005 mm (0.0002"). From prototype development to full-scale production, our machining capabilities ensure consistent quality, reliability, and speed for demanding industries.

Our global manufacturing network offers the agility, cost efficiency, and technical precision needed to meet the requirements of automotive, medical, electronics, and communications applications.

Precision CNC turning, milling, and screw machining for small to medium components

Integrated production: Sub-assembly and encasing lines for complete solutions—often combined with plastic injection molding, wire harness assembly, or PCB assembly in final assemblies

Contact us today to discuss your precision machined component requirements.